Materials

DFI offers a wide range of raw materials to accommodate your required functionality and budget.

The following are available in a variety of densities and compression strengths.

• Cross-linked Polyethylene Foam (PE)

• Polyurethane Foam (PU)

• Reticulated Polyurethane Foam (Filter Foam)

• Expanded Polystyrene (EPS)

• Expanded Polyethylene (EPE)

• Expanded Polypropylene (EPP)

Our highly skilled team has manufactured custom-foam solutions for a wide array of industries, including aerospace, automotive, marine, medical, and packaging, among others. In collaboration with our expert engineers we provide our partners full support throughout the complete design, fabrication, and integration process.

Contact DFI today to learn more about your custom foam solution.

Featured Materials

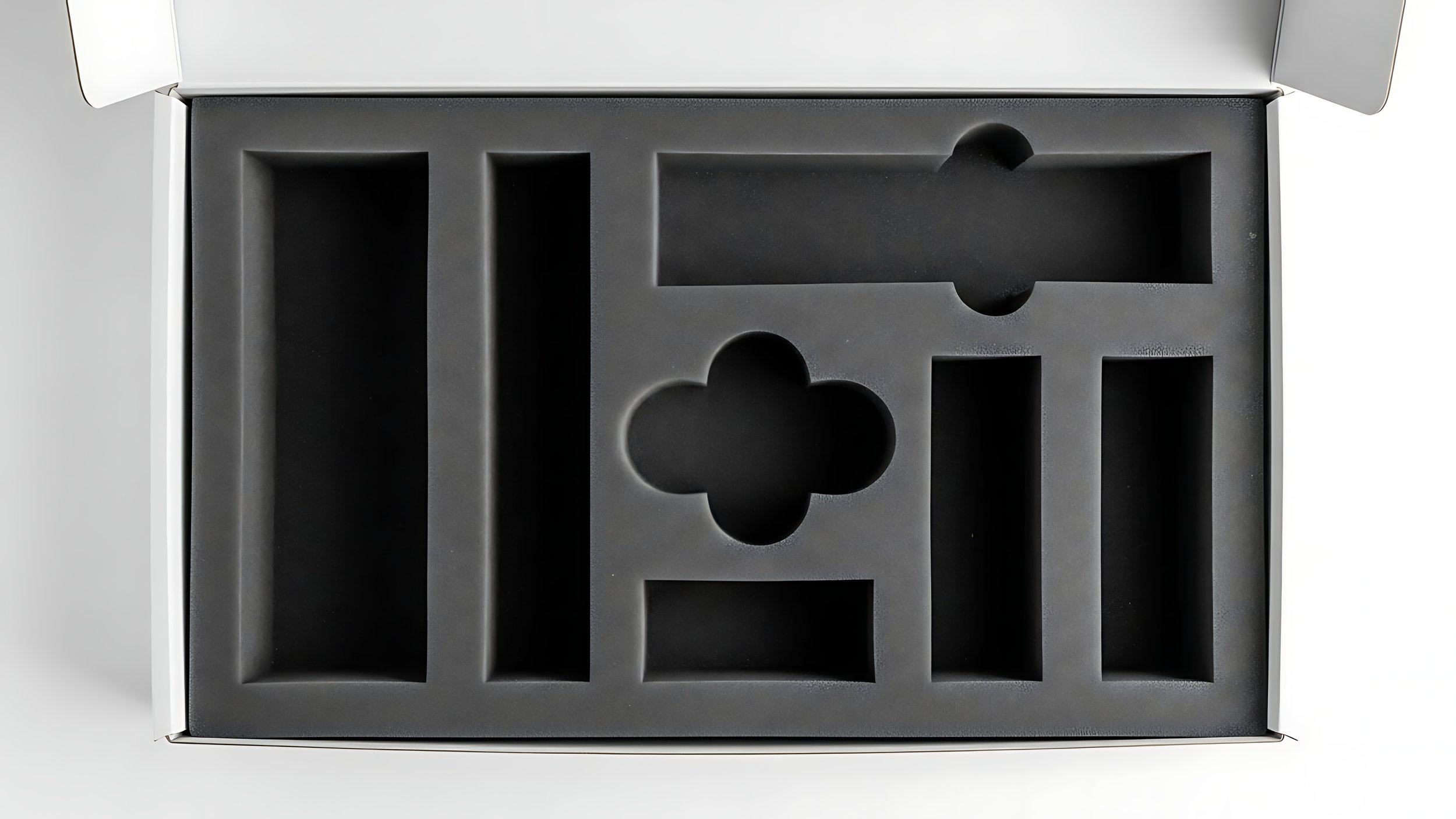

Polyurethane foam offers exceptional flexibility and comfort with excellent cushioning and energy absorption. Its adaptable structure makes it ideal for protective packaging, furniture, bedding, and noise-reduction solutions.

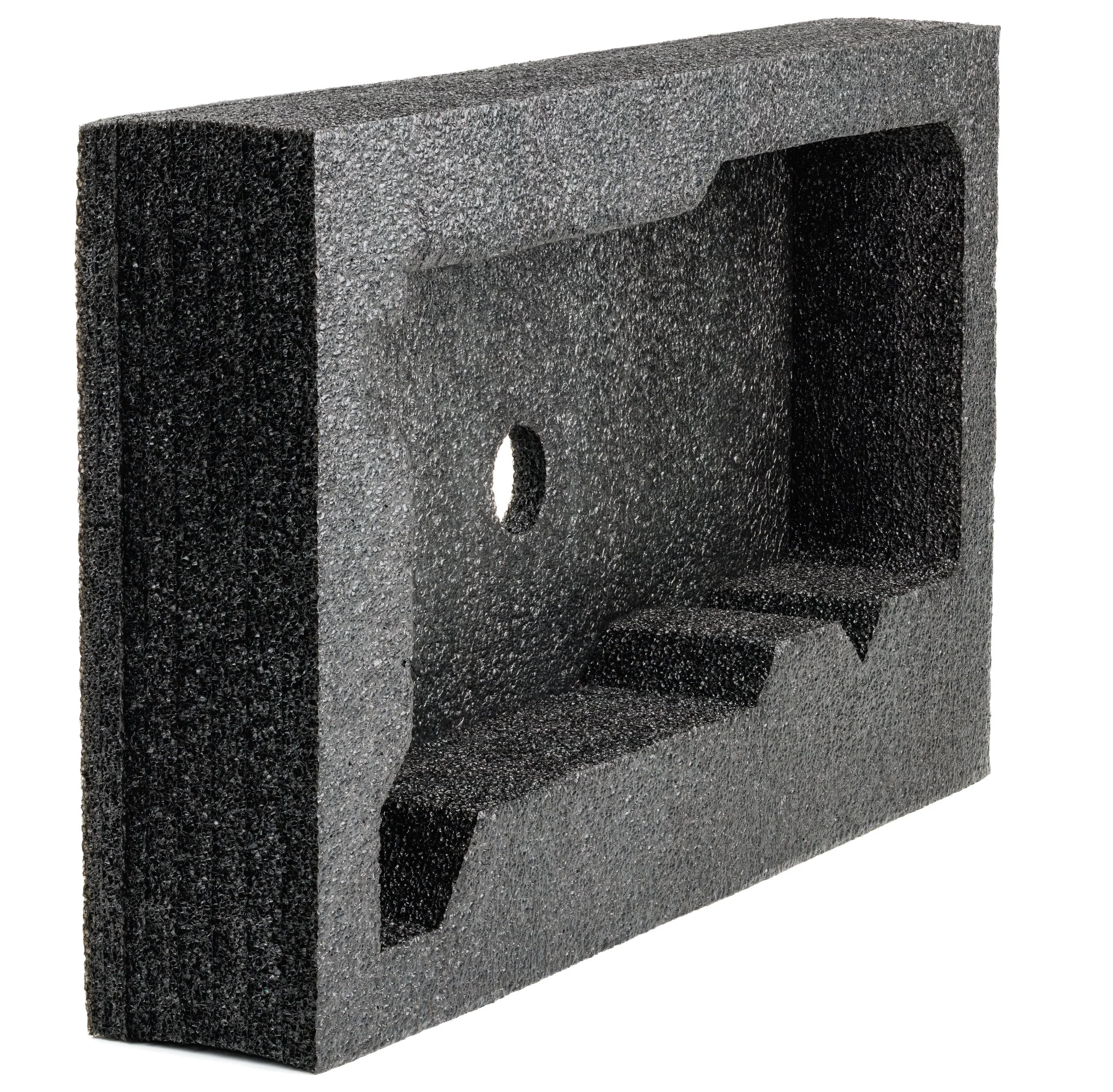

EPP foam is a resilient, closed-cell polypropylene foam offering high energy absorption, thermal insulation, and chemical resistance. It is commonly used in automotive components, protective packaging, and returnable transport systems.

Reticulated foam is an open-cell polyurethane foam designed for high airflow and effective filtration. Its porous structure allows air, water, and liquids to pass freely while capturing particulates, making it ideal for filtration, ventilation, and acoustic applications.

EPS foam is a lightweight, rigid material that provides reliable insulation and impact protection. It is commonly used for protective packaging, thermal insulation, and molded components where strength, cushioning, and cost efficiency are required.

Crosslinked polyethylene foam is a closed-cell material known for its fine cell structure, durability, and enhanced performance characteristics. It offers excellent shock absorption, thermal insulation, and resistance to moisture, chemicals, and abrasion. Crosslinked foam is commonly used in Class A surface protective packaging, insulation, medical and automotive components, and applications requiring consistent density, clean appearance, and long-term reliability.

Learn More

DFI partners with your team from concept to production.